CERAMIC 3D PRINTER

CERAMIC 3D PRINTER

CERAMIC 3D PRINTER

CERAMIC 3D PRINTER

NUBE

CERAMIC 3D PRINTER

CERAMIC 3D PRINTER

CONTEXT: Located in one of the nerve points of the city of Córdoba, Argentina and next to a great flow of circulations the new bus terminal has left without use its ex car parking.

The project of Nube is born of this analysis seeking to take advantage and to RECYCLE this public space, to generate a meeting between the citizens and the travelers.

QUILPO

QUILPO

QUILPO

QUILPO

QUILPO

CERAMIC 3D PRINTER

CERAMIC 3D PRINTER

CERAMIC 3D PRINTER

CERAMIC 3D PRINTER

CERAMIC 3D PRINTER

CERAMIC 3D PRINTER

CERAMIC 3D PRINTER

CERAMIC 3D PRINTER

CERAMIC 3D PRINTER

Nicolás Olmos

DESIGN

Nicolás Olmos

ARCHITECTURE

The progress of this project can be quantified in two phases, where the same digital technologies are researched and developed, meanwhile the raw material changes, due to manipulation approaches and impact on health issues:

Phase 1: PVC recycling approach

Phase 2: Leather used for emphasis on demonstrating how these new digital tools are shifting the contemporary practices of fashion design.

The shift in raw material is clearly and correctly justified, as manipulation of PVC causes health and sustainability issues, in small workshops and it would need a very complex infrastructure to be implemented for the development of one project.

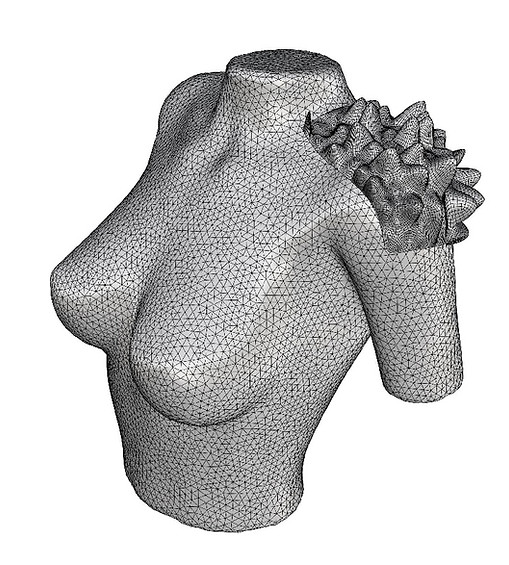

The Project introduces innovation using new technologies, in a traditional sector such as the Leather one. The combination of artisan work with the digital technologies employed in this project: 3D modeling, CNC milling, moulding and vacuum forming offer a wide range of possibilites for new designs.

The main focus of the new collection design was on organic shapes, bubbles, and several garments and accessories were developed: 2 belts, 1 bag, 1 coat, 2 shoulder pieces and 1 sleeve.

CERAMIC 3D PRINTER

CERAMIC 3D PRINTER

CERAMIC 3D PRINTER

CERAMIC 3D PRINTER

CERAMIC 3D PRINTER

CERAMIC 3D PRINTER

CERAMIC 3D PRINTER

CERAMIC 3D PRINTER

This series is inspired by the mathematics found in nature, exploring the freedom of its compositions and trying to capture the movements generated in it. Through the molding of leather, biodegradable material, combines traditional techniques, increasingly neglected with contemporary technology and digital fabrication to give birth to this collection of leather bags.

3DPRINTER

Technique: mix between old and contemporary molding techniques

Machines: milling machine - sewing leather machine - vacuum - industrial oven - laser machine - 3D printer

Materials: leather - plastics

Programs: Rhinoceros - Grasshopper - Cura

Collaboration with Anastasia Pistofidou for the MadaDesign Worth project

ESTHER PERBANDT COLLECTION